CHECK ENGINE

Why witness Check Engine lights?

Almost every driver has happened or is about to happen to it. We refer to the witness of the board called "Check Engine". If this witness remained lit means that your car's onboard computer detected a problem.First I will explain how it works. Your car is equipped with an onboard computer that controls the engine and transmission. This botd computer monitors signals from the various sensors and adjusts engine and transmission the performances so as to reduce fuel consumption and level of pollutants emitted.

The onboard computer can be checked using an interface diagnostic (OBD II). When the onboard computer detects a certain defect reported by a sensor witness dashboard Check Engine lights and trip computer stores an error code.

To diagnose the problem, it must connect the driver with a scanning interface and visualize that code. The code itself does not say exactly what component is faulty but say what parameters does not function properly. The driver will have to make further tests to find fault, then you have to reset the error so that the witness Check Engine board to the left.

Common Errors that can ignite witness Check Engine

On older vehicles, the ignition of this witness can mean failure of a MAP sensor, MAF sensor, worn spark plugs, plugs interrupted or clogged EGR. New cars have more electronic components, and is therefore virtually impossible to find the problem without scanning errors stored in the onboard computer.

If your car is new, the best choice is to go right to representation. The repairs may be covered under warranty. Car dealerships and mechanics usually have skilled technicians, trained for specific problems your car type.

Possible problems

Lambda senzor

"Gas control" lights up when the ECU detects problems with gas sensors. Specifically, the lambda probes. In such situations recommended first step is to make a diagnosis. It will not only see the error codes, but also readings of sensors

SL1 finds in the cabin as the engine hood up in the middle of metallic material with a warning "Hot"

SL 2:01 Find on the exhaust manifold by combining the four pipes saxophone. (As can be seen behind the engine).

Possible causes.

- Malfunctioning fuel combustion. (black smoke)

- The possible presence of oil in the combustion chamber. - Segments aligned. (white smoke smelling of burnt oil).

- Possible missfire on one cylinder (spark or induction coil) - symptom - heavy drag, increased noise, high consumption.

- Contact imperfect of jacks lambda probes or frayed wires.

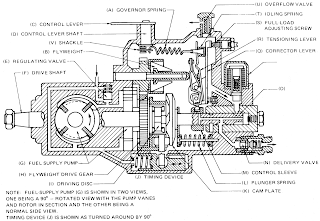

Injection pump

Injection pump

Solenoid, obscure power supply and high pressure chamber. If the valve does not open or if catch air on the O-rings, pump pressure is below the opening of the injectors.

The fuel injection system lies at the very heart of the diesel engine. By pressurising and injecting the fuel, the system forces it into air that has been compressed to high pressure in the combustion chamber.The diesel fuel injection system consists of:

- fuel injection pump - pressurises fuel to high pressure

- high-pressure pipe - sends fuel to the injection nozzle

- injection nozzle - injects the fuel into the cylinder

- feed pump – sucks fuel from the fuel tank

- fuel filter - filtrates the fuel

Functions of the system

The diesel fuel injection system has four main functions:

The diesel fuel injection system has four main functions:Feeding fuel

Pump elements such as the cylinder and plunger are built into the injection pump body. The fuel is compressed to high pressure when the cam lifts the plunger, and is then sent to the injector.

Adjusting fuel quantity

In diesel engines the intake of air is almost constant, irrespective of the rotating speed and load. If the injection quantity is changed with the engine speed and the injection timing is constant, the output and fuel consumption change. Since the engine output is almost proportional to the injection quantity, this is adjusted by the accelerator pedal.

Adjusting injection timing

Adjusting injection timingIgnition delay is the period of time between the point when the fuel is injected, ignited and combusted and when maximum combustion pressure is reached. As this period of time is almost constant, irrespective of engine speed, a timer is used to adjust and change injection timing – enabling optimum combustion to be achieved.

Atomising fuel

When fuel is pressurised by the injection pump and then atomised from the injection nozzle, it mixes thoroughly with air, thus improving ignition. The result is complete combustion.

Injectors

The spark-ignition engines these valves are controlled electronically controlled by the engine computer "ECU" (Electronic Control Unit). The compression-ignition engines, even those that appeared modern engines with common rail, injectors operation was done by hydraulic pressure achieved by the injection pump.

Is critical in the injection system is a fuel injection jet, the way in which it is sprayed.

An ideal splash of fuel is obtained if the jet has splashed out finer and inwards drops somewhat bulky. Through this structure first light jet finer spray, followed by thicker, leading to a slower burn and uniform, so a finer increase pressure in the combustion chamber.

The components of the injectorThe injector consists of:

The components of the injectorThe injector consists of:-Body and nozzle needle. Both are made of high quality steel, built to tolerances between 0002-0003 mm. Therefore only be replaced together. Depending on the engine, the nozzle body has a plurality of holes. Number of holes is between 5 (cars) and 14 (higher power diesel engine) and their diameter ranges from 0.15 mm (car) and 0.4 mm (truck). The number, angle, size and flow conditions affect spraying jet nozzle hole, which, according to quantity, pressure, combustion chamber geometry, compression and combustion engine temperature determines the quality of the fuel.

-Electric coil. The injector, more recently, is an activation element or a coil to produce a magnetic field, or tending more towards activating piezo.

-Injector body with the flow and return connections for fuel.

-The control piston and the springs acting upon it.

-Electric cable connector.

Malfunctions

The main mistake of fuel injection is incorrect spray, which can be distinguished by:

-Burning chatter: Much of the injected fuel burn suddenly. It is characterized by the famous "noise" diesel engine which can increase fuel consumuli, loss of power, poor quality exhaust system and damage the motor bearings.

-Local overheating: When the jet beam is deajustat achieve piston head, which can cause burning or holes in it.

-Interruption of the lubrication layer: In the case where the fuel jet is designed in the cylinder wall, the layer of grease that was washed. Because little fuel lubrication, engine seizure occurs.

No comments:

Post a Comment