ENGINE FAULTS

Wednesday, 16 December 2015

- Airbag lit bulb E46 models due to failure of the passenger seat net- Crankshaft pulley diesel models have rubber core and over time become consumers- Oil spills continue to build gasket older petrol engines- Wheels "lying" rear bushing wear due to "creaking"- E46 models wear mechanism of the power windows lead to bothersome noises hoisting and lowering

- Enter LIMP MOD engine bearings of the turbine because of the blockage TDI oil consumption big enough, even newer engines trepidation leaving the place the wheel bearings because wear black smoke for excessive sudden acceleration is a result of incomplete combustion of various causes turbine fuel or low fuel gasoline injectors- binding capacity of specific uproar smoke rings and rings wear the blue and white valve

- Board that senses light bulbs in various electrical problems

CHECK ENGINE

Why witness Check Engine lights?

Almost every driver has happened or is about to happen to it. We refer to the witness of the board called "Check Engine". If this witness remained lit means that your car's onboard computer detected a problem.First I will explain how it works. Your car is equipped with an onboard computer that controls the engine and transmission. This botd computer monitors signals from the various sensors and adjusts engine and transmission the performances so as to reduce fuel consumption and level of pollutants emitted.

The onboard computer can be checked using an interface diagnostic (OBD II). When the onboard computer detects a certain defect reported by a sensor witness dashboard Check Engine lights and trip computer stores an error code.

To diagnose the problem, it must connect the driver with a scanning interface and visualize that code. The code itself does not say exactly what component is faulty but say what parameters does not function properly. The driver will have to make further tests to find fault, then you have to reset the error so that the witness Check Engine board to the left.

Common Errors that can ignite witness Check Engine

On older vehicles, the ignition of this witness can mean failure of a MAP sensor, MAF sensor, worn spark plugs, plugs interrupted or clogged EGR. New cars have more electronic components, and is therefore virtually impossible to find the problem without scanning errors stored in the onboard computer.

If your car is new, the best choice is to go right to representation. The repairs may be covered under warranty. Car dealerships and mechanics usually have skilled technicians, trained for specific problems your car type.

Possible problems

Lambda senzor

"Gas control" lights up when the ECU detects problems with gas sensors. Specifically, the lambda probes. In such situations recommended first step is to make a diagnosis. It will not only see the error codes, but also readings of sensors

SL1 finds in the cabin as the engine hood up in the middle of metallic material with a warning "Hot"

SL 2:01 Find on the exhaust manifold by combining the four pipes saxophone. (As can be seen behind the engine).

Possible causes.

- Malfunctioning fuel combustion. (black smoke)

- The possible presence of oil in the combustion chamber. - Segments aligned. (white smoke smelling of burnt oil).

- Possible missfire on one cylinder (spark or induction coil) - symptom - heavy drag, increased noise, high consumption.

- Contact imperfect of jacks lambda probes or frayed wires.

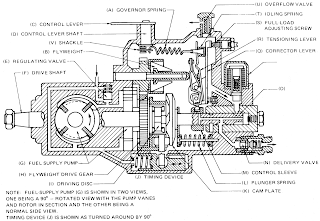

Injection pump

Injection pump

Solenoid, obscure power supply and high pressure chamber. If the valve does not open or if catch air on the O-rings, pump pressure is below the opening of the injectors.

The fuel injection system lies at the very heart of the diesel engine. By pressurising and injecting the fuel, the system forces it into air that has been compressed to high pressure in the combustion chamber.The diesel fuel injection system consists of:

- fuel injection pump - pressurises fuel to high pressure

- high-pressure pipe - sends fuel to the injection nozzle

- injection nozzle - injects the fuel into the cylinder

- feed pump – sucks fuel from the fuel tank

- fuel filter - filtrates the fuel

Functions of the system

The diesel fuel injection system has four main functions:

The diesel fuel injection system has four main functions:Feeding fuel

Pump elements such as the cylinder and plunger are built into the injection pump body. The fuel is compressed to high pressure when the cam lifts the plunger, and is then sent to the injector.

Adjusting fuel quantity

In diesel engines the intake of air is almost constant, irrespective of the rotating speed and load. If the injection quantity is changed with the engine speed and the injection timing is constant, the output and fuel consumption change. Since the engine output is almost proportional to the injection quantity, this is adjusted by the accelerator pedal.

Adjusting injection timing

Adjusting injection timingIgnition delay is the period of time between the point when the fuel is injected, ignited and combusted and when maximum combustion pressure is reached. As this period of time is almost constant, irrespective of engine speed, a timer is used to adjust and change injection timing – enabling optimum combustion to be achieved.

Atomising fuel

When fuel is pressurised by the injection pump and then atomised from the injection nozzle, it mixes thoroughly with air, thus improving ignition. The result is complete combustion.

Injectors

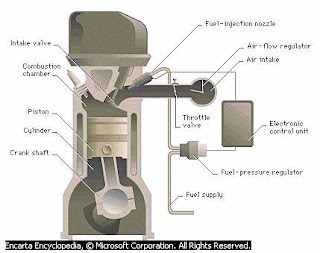

The spark-ignition engines these valves are controlled electronically controlled by the engine computer "ECU" (Electronic Control Unit). The compression-ignition engines, even those that appeared modern engines with common rail, injectors operation was done by hydraulic pressure achieved by the injection pump.

Is critical in the injection system is a fuel injection jet, the way in which it is sprayed.

An ideal splash of fuel is obtained if the jet has splashed out finer and inwards drops somewhat bulky. Through this structure first light jet finer spray, followed by thicker, leading to a slower burn and uniform, so a finer increase pressure in the combustion chamber.

The components of the injectorThe injector consists of:

The components of the injectorThe injector consists of:-Body and nozzle needle. Both are made of high quality steel, built to tolerances between 0002-0003 mm. Therefore only be replaced together. Depending on the engine, the nozzle body has a plurality of holes. Number of holes is between 5 (cars) and 14 (higher power diesel engine) and their diameter ranges from 0.15 mm (car) and 0.4 mm (truck). The number, angle, size and flow conditions affect spraying jet nozzle hole, which, according to quantity, pressure, combustion chamber geometry, compression and combustion engine temperature determines the quality of the fuel.

-Electric coil. The injector, more recently, is an activation element or a coil to produce a magnetic field, or tending more towards activating piezo.

-Injector body with the flow and return connections for fuel.

-The control piston and the springs acting upon it.

-Electric cable connector.

Malfunctions

The main mistake of fuel injection is incorrect spray, which can be distinguished by:

-Burning chatter: Much of the injected fuel burn suddenly. It is characterized by the famous "noise" diesel engine which can increase fuel consumuli, loss of power, poor quality exhaust system and damage the motor bearings.

-Local overheating: When the jet beam is deajustat achieve piston head, which can cause burning or holes in it.

-Interruption of the lubrication layer: In the case where the fuel jet is designed in the cylinder wall, the layer of grease that was washed. Because little fuel lubrication, engine seizure occurs.

Frequent engine problems

- Boiling coolant, without leading to this specific case

- Bubbles in the expansion vessel (from Lost in compression cooling system)

- Oil in coolant

- Water in the sump, a brownish foam on the oil filler cap and dipstick on control

- Loss of coolant without a clear explanation (hose burst, etc ..)

A blown head gasket may cause a number of different symptoms. Coolant in the engine oil, an engine misfire or oil leaking from the engine could all be a symptom. Each of these symptoms could also have other causes and an actual blown head gasket may show none of the above symptoms.

Diagnosing head gasket symptoms

It is easy to be mislead, when trying to diagnose a bad head gasket. Symptoms will often vary considerably, depending on how the gasket fails. The term "blown head gasket" does NOT necessarily describe a single thing. Head gaskets may fail in several different ways. With each failure type different symptoms may result. The symptoms each person sees depend on how and where the head gasket fails.

To make diagnosis even more confusing, other things may cause the same symptoms as a head gasket failure. Another issue may be multiple failures which can cause more than one symptom. For example, a restricted radiator may cause an engine to overheat, very much the same as a head gasket failure. The farther we drive the vehicle, the more it may overheat. Often, intake gaskets cause coolant in the oil. Coolant in the oil is often mistaken as a head gasket. Each of these symptoms may suggest a head gasket problem, but may have another explanation. Diagnosing the problem requires experience and a logical approach.

Consequences of not replacing a bad head gasket

Because of the difficulty in diagnosing and the expense of repairing a head gasket, we may be tempted to let it go. This is a big mistake. Depending on the type of failure, far more damage will soon occur.If coolant enters the exhaust, through the combustion chamber, the catalytic converter(s) is often damaged. Coolant in the engine oil may destroy the engine, by breaking down lubrication. Combustion gases that leaks into the coolant usually results in continued overheating and more damage. Hydrocarbons entering the coolant will also greatly increase corrosion. This may destroy the radiator, heater core and other expensive components.

Types of head gasket failure

Adding to the problem of diagnosis may be other factors. For example, a warped or cracked cylinder head will produce the exact symptom of a blown head gasket. An external inspection will only determine the problem is head gasket related. This may mean a blown gasket, warped or cracked cylinder head or other problems in the area. For instance corrosion on the head gasket surface will cause leakage, though technically not a blown gasket. Removing the head and testing it is the only way to know the extent of the damage.Engine misfire caused by a head gasket

A head gasket that fails between cylinders will generally cause a misfire and perhaps few other symptoms. With a failure between cylinders, compression from one cylinder leaks into another. Lowered compression results in a rough idling engine. Damage of this type may not cause overheating, coolant in the oil or any other outward sign. Many people overlook this as the cause of engine misfires, because the blown head gasket does not also give the other more common symptoms. When the head gasket fails between a cylinder and the coolant port, coolant may leak into the cylinder. This often results in misfires on startup, especially after the engine is run, turned off and restarted. This type of failure may not show with a compression test. Pressuring the cooling system and then starting the engine, may make the misfire more noticeable. Coolant on the tip of a spark plug is another dead give away.Overheating from a blown head gasket

When a head gasket fails between a combustion chamber and the cooling system, a loss of coolant and overheating are often the result. This may be intermittent in nature. For instance the vehicle may only overheat after driving a distance. With short trips, symptoms may not show up. This type of failure is very damaging. Not only does overheating continue to get worse, combustion gasses are corrosive and may severely damage the cooling system. Other symptoms may include repeat failure of hoses, radiators and cooling system components. Pressure may build in the cooling system until the weakest link fails. Replacing the component causes the next weakest part to fail.

Frequently this type problem develops after an engine overheat caused by another reason. For example, a leaking water pump may cause the engine to over heat. We replace the pump, but the overheating continues. In other instances, the water pump replacement cures the overheat but it starts again several months later. The original overheat crushed the head gasket, which took time to show a problem. This can be confusing and often we have forgotten the original cause when symptoms return.

Oil in the coolant and coolant in the oil

Head gaskets may also fail between the coolant passages and the lubrication system. This type failure may show up as oil in the coolant or coolant in the oil. Most often a swollen seal on the radiator cap is the first symptom. Glycol in engine oil is much harder to detect. Unlike pure water, glycol may not turn the oil milky. Unfortunately it will destroy the ability of the oil to lubricate and change the viscosity of the oil. An oil-testing laboratory can check an oil sample and identify glycol contamination.An external oil leak

It is also common to find failures between an oil passage and the outside. Such damage results in an external oil leak, and possibly no other symptom.An oil leak from a head gasket is not common and sometimes it is mis-diagnosed. For instance we may think oil leaking from the head gasket is leaking from a valve cover. Because valve cover leakage is far more common, this is an easy mistake to make. Other times the oil may drip from the area below the transmission. Gravity causes the oil to flow down and this is the lowest point. We may mistake this as a rear-main seal or oil-pan gasket leak, if we are not careful.

It is also possible for head gaskets to fail in multiple ways. Multiple failures often produce combinations of the symptoms listed.

Hydrocarbon coolant testing

A handy procedure for identifying a blown head gasket is the hydrocarbon test. When combustion gasses leak into the coolant, we may detect the unburned hydrocarbons. We use a tool, made for the purpose, and special chemicals that change color when exposed to hydrocarbons.

|

Basic Car Parts

Parts Of Your Car

Air cleaner/filter: Air is drawn through it. Contains a filter that blocks dirt before it can enter the engine.Air intake manifold: Air is distributed into the combustion chamber.

Battery: Supplies the initial electrical power that starts the engine.

Carburetor: Most new cars now have fuel injected engines. Older vehicles have carburetors. This gadget mixes air and fuel in the proper ratio for burning in the engine’s combustion chambers.

Coolant reservoir (tank): Holds hot coolant (antifreeze) that overflows from the radiator and also draws back into the radiator as it is needed.

Distributor: Distributes high voltage electricity to the spark plugs, one at a time.

Exhaust manifold: Set of pipes, one for each cylinder that conducts exhaust away from cylinders.

Fuel injection system: Sprays controlled amount of fuel directly into either the intake manifold or combustion chambers, resulting in a very precise air to fuel ratio that improves fuel economy.

Muffler: The interior “baffles” and tubes quiet the explosive release of exhaust.

Power steering reservoir: This reservoir contains fluid for your power steering system. Once the reservoir cap is unscrewed the cap will consist of a dip stick. This will identify the fluid levels.

Brake fluid reservoir: The brake fluid level can be inspected by the plastic box or bottle by the fire wall on the driver side.

Brake fluid reservoir: The brake fluid level can be inspected by the plastic box or bottle by the fire wall on the driver side.Disc brakes: A metal disk that spins with the wheel that the brake pad uses to pressure against to stop.

Oil dip stick: The stick that’s used to check the level of the motor oil.

Rear Axle: A shaft that connects the power from the transmission to the wheels.

Radiator: The device that helps to remove heat from the cooling system as coolant passes through it.

Basic Engine Parts

The core of the engine is the cylinder, with the piston moving up and

down inside the cylinder. The engine described above has one cylinder.

That is typical of most lawn mowers, but most cars

have more than one cylinder (four, six and eight cylinders are common).

In a multi-cylinder engine, the cylinders usually are arranged in one

of three ways: inline, V or flat (also known as horizontally opposed or boxer), as shown in the following figures.

The core of the engine is the cylinder, with the piston moving up and

down inside the cylinder. The engine described above has one cylinder.

That is typical of most lawn mowers, but most cars

have more than one cylinder (four, six and eight cylinders are common).

In a multi-cylinder engine, the cylinders usually are arranged in one

of three ways: inline, V or flat (also known as horizontally opposed or boxer), as shown in the following figures.Different configurations have different advantages and disadvantages in terms of smoothness, manufacturing cost and shape characteristics. These advantages and disadvantages make them more suitable for certain vehicles.

Figure 2. V - The cylinders are arranged in two banks set at an angle to one another.

Figure 3. Flat - The cylinders are arranged in two banks on opposite sides of the engine.

Let's look at some key engine parts in more detail.

Let's look at some key engine parts in more detail.Spark plugThe spark plug supplies the spark that ignites the air/fuel mixture so that combustion can occur. The spark must happen at just the right moment for things to work properly.

ValvesThe intake and exhaust valves open at the proper time to let in air and fuel and to let out exhaust. Note that both valves are closed during compression and combustion so that the combustion chamber is sealed.

PistonA piston is a cylindrical piece of metal that moves up and down inside the cylinder.

Piston ringsPiston rings provide a sliding seal between the outer edge of the piston and the inner edge of the cylinder. The rings serve two purposes:

- They prevent the fuel/air mixture and exhaust in the combustion chamber from leaking into the sump during compression and combustion.

- They keep oil in the sump from leaking into the combustion area, where it would be burned and lost.

Connecting rod

The

connecting rod connects the piston to the crankshaft. It can rotate at

both ends so that its angle can change as the piston moves and the

crankshaft rotates.

The

connecting rod connects the piston to the crankshaft. It can rotate at

both ends so that its angle can change as the piston moves and the

crankshaft rotates.CrankshaftThe crankshaft turns the piston's up and down motion into circular motion just like a crank on a jack-in-the-box does.

SumpThe sump surrounds the crankshaft. It contains some amount of oil, which collects in the bottom of the sump (the oil pan).

Subscribe to:

Comments (Atom)